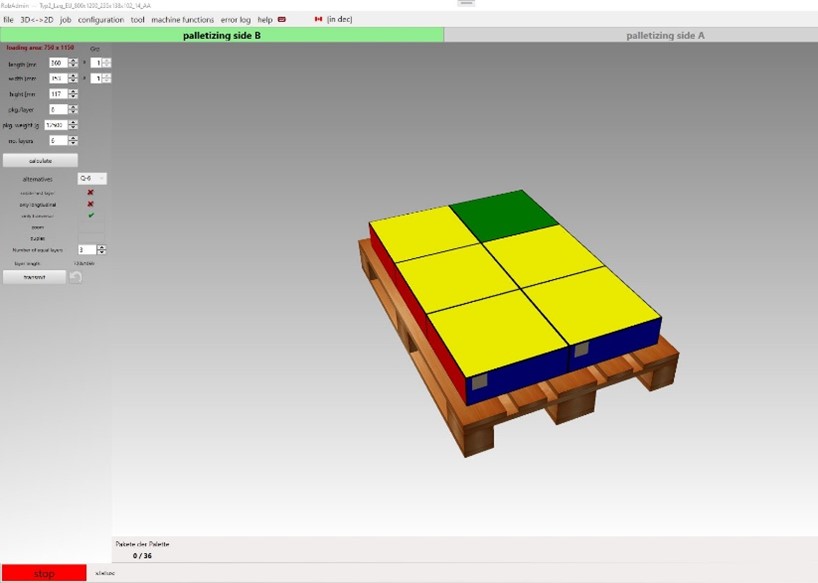

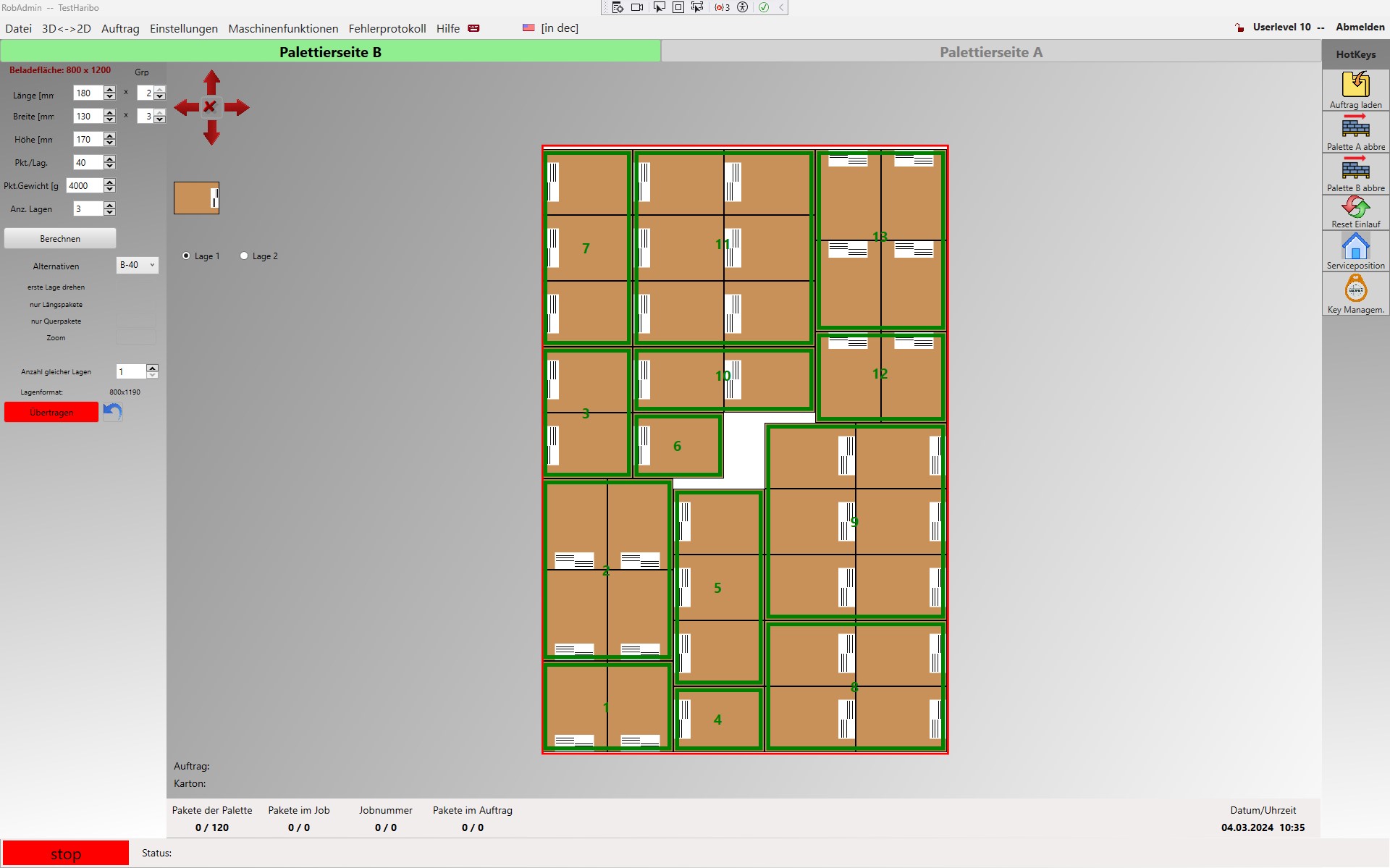

SEGBERT layer program PalAdmin

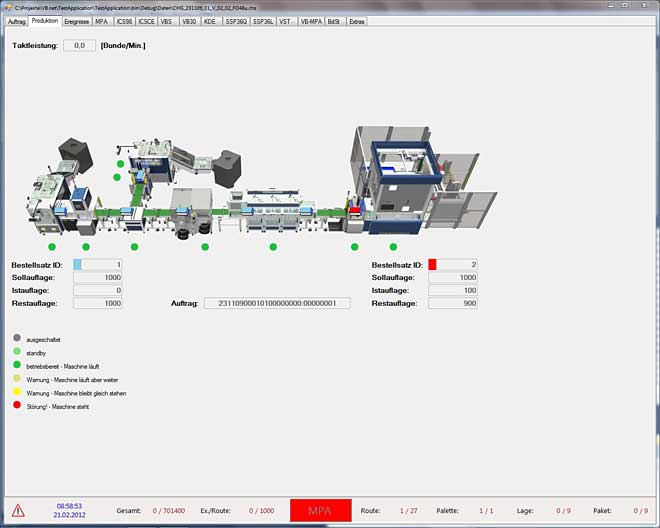

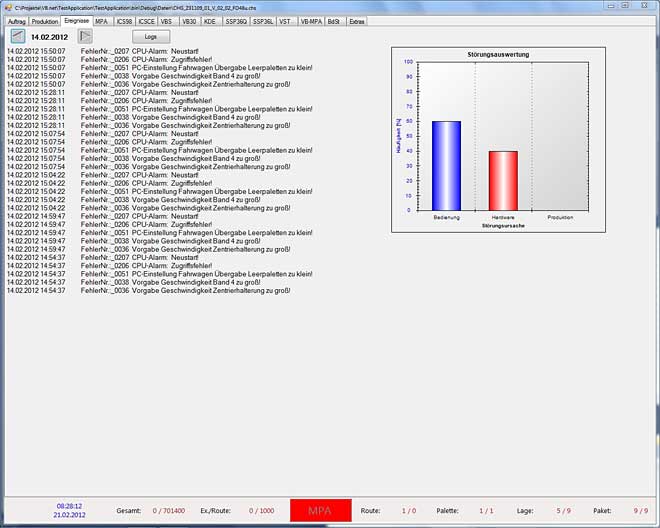

- Integrated in all Segbert layer palletizers

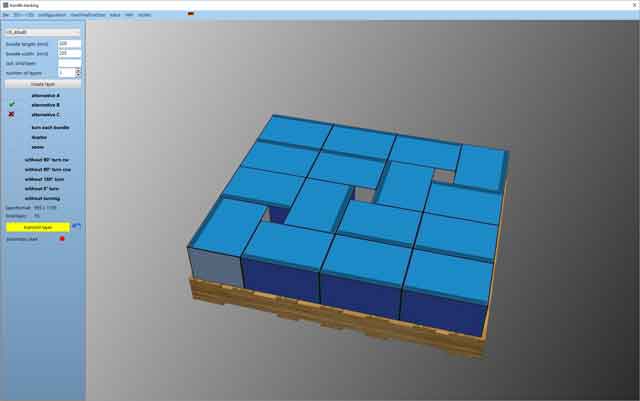

- Real-time calculated 3D layer patterns

- Flexible and manual adjustment of layer patterns

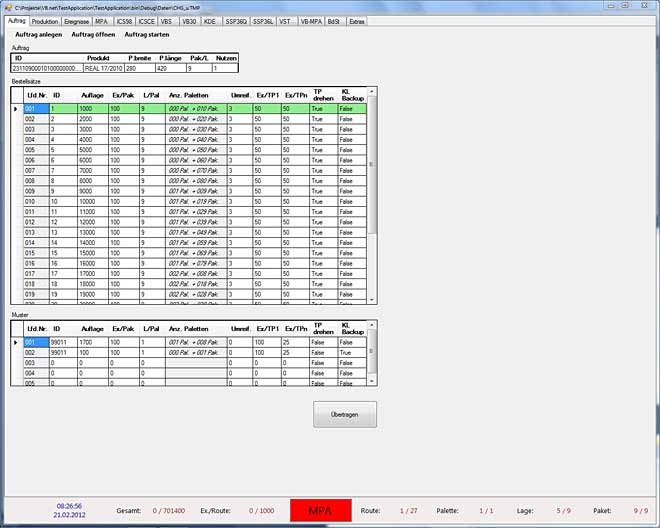

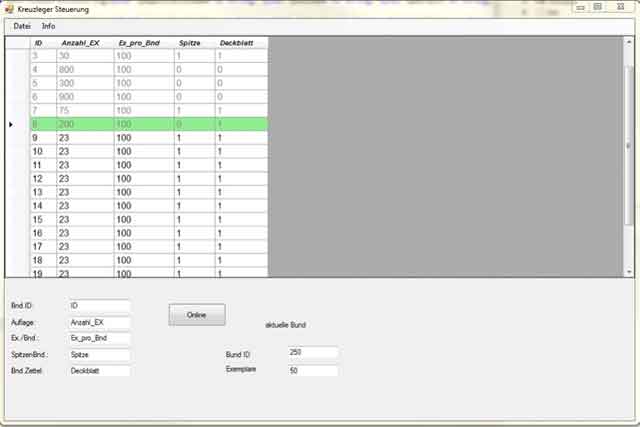

- Input and management of various jobs

- Intuitive user guidance

- Standardized interfaces webservice XML, exchange format CSV and XML, FTP-client, SMB-client for access to network files

- Integrated pallet label configurator

- An additional single-user office-version for job preparation is available as an option